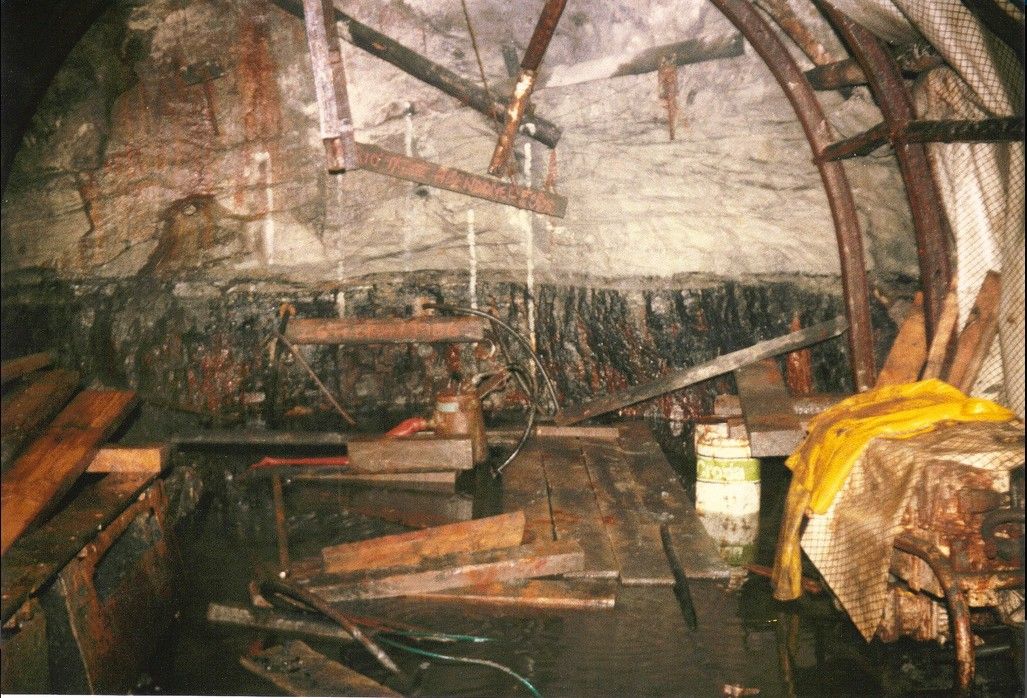

R10s TAILGATE - ITS A DEPRESSING BLACK AND WHITE HOLE

high pit wilma :- Note the "epitaph"for the drivage..AND the colliery... on the face timbers..[zoom!]

Kevnorth :-Seeing the NCB Black & White cheque plastic sheeting on the right in this photo brings back a few childhood memories! My Dad built a garage out of salvaged wood &used that plastic sheeting to waterproof the roof, back & sides! luckily because we lived in a colliery row of houses it didnt stand out that much lol!

BigLoada :-Haha Kev I think everywhere in the pit villages used that pit plastic! We had loads on our garage roof too!

high pit wilma :- Heh! Heh! A blast from thi past eh? Kev?!!!..funnily enough,it didn't keep us dry, cos it got blaan ti hell wi' thi shots!

Kevnorth :- Wilma an update on the old pit plastic... I've recently moved up to Hadston and guess what my next door neighbours garden shed has the self same plastic sheeting on the roof and back, he swears it still holds up and doesnt leak a bit but he hasnt got a clue how long it's been on there as he's only lived there 25 years!

Dr. Drewboy :-that looks really sad!

oildrum1 :- The black & white sheeting was "Brattice" or "Brattice cloth", a fire resistant cloth or laterly plastic used to divert or confine the flow of air underground. But as mentioned had many other uses :-)

Great underground pic too

high pit wilma :-Hi Drewboy,and Oildrum1!

Thanks for your comments guys,yes,it had many uses,i still have some in my dark loft space,to cover the xmas tree,and tree-toys-boxes....and iv'e been finished the pits since 1987!!!!![25 years],but mind,it's gone as hard as a board,and just stays in the shape of the bundled-up tree sections,when i bring the tree down for xmas!

In modern pits like Bates,especially in the 3/4 seam,where the ventilation was so fierce,due to being not far from the shaft bottom,[only a couple of miles],that this stuff was never used for it's original purpose...diverting air......it was more used to lay over electrical panel-boxes and 6000volt transformers!!![to protect the gear from roof-water]

Stephen Franks :- Looks wet!!

high pit wilma :- Aye Wesdtrie,we used to say that you canna get any wetter than wet!!,and God gie yi waataproof skin,so ye'll dry oot the syem way ye got wet!!

What isn't so evident is the amount of "droppers," and "runners",teemin in from the roof constantly,noo when ye were looking up ti put ya timbers in,or drilling ya top holes,ye got both a gud eyeful,and earful of salty seawater,which,upon analysis,was proven to be six times saltier than seawater,and three times more corrosive,which just seized up all the electrical switchgear handles over the space of a weekend.

Electricians and fitters had a permanent run of weekend work to do maintainance of the gear to keep it in working order . Everything on the coalfaces used to rot quicker than it would on any other face in the country,so Bates was used as a base to test out prototype machinery.

The crack was,if it works doon the three-quarter,it'll work anywhere in the world!

Recommended Comments

Create a free account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now