-

Posts

1,504 -

Joined

-

Last visited

-

Days Won

130

Content Type

Forums

Gallery

Events

Shop

News

Audio Archive

Timeline

Image Comments posted by HIGH PIT WILMA

-

-

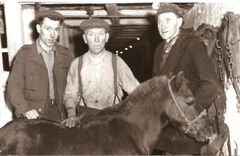

One of my Neighbours at Hollymount Square,in the early 1950's was a fella called "Aad Singer Dixon" ,and he was one of the Horsekeeper's from the year Dot,they used to say..and this guy looks like him to my mind..I was only three years old when we moved there,but I grew up with the Dixons,until I got Married in 1967,but Singer had sadly Passed away by then. I remember his Grandson Brian visiting every other night,with his Parents,and through the windows at night we used to hear Old Singer shouting ,as he waved his family off for the night ..."Gudneet,see ye thi morn!"..I can hear his voice noo as a type!! The horse's Collar and Yemsicks can just be seen at the right side hanging on the hook. Great Pic! Cheers Bill.

-

1

1

-

-

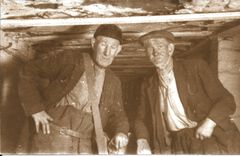

Note their pants!!.."Fustons"...indestructible thick warm material,most Miners wore Fustons,it was like ...what else wud ye wear doon a black hole?...not ya Wedding Suit! See the Steel corrugated Straps,[or "Planks"] holding the roof up? They were 6' long and canny heavy! Aboot three or four years ago,me and LBJ [me wee Lab x Dog],were waaking back from owa the Bomar fields ahent wor hoose,and a got me eye on summick familiar,sticking oot the thick bushes,next ti the Farmer's fence.A howked on and pulled it oot,it was one of these steel straps,bent at right angles,wi the weight of the roof underground,and it came from the Bomar pit heaps when they levelled it oot..noo hoo it ended up where it was owa the field a divvent knaa,but a fetched it yem on me shoulder,and mind,a was knackered when a got back yem!A hae it at the bottom of me garden as a feature,next ti me fence!! Just a little reminder of when a was strong enough ti lift them with one hand up ti the roof,and put a Lazy-Man prop in ti haad it there,so ye cud knock a prop in at each end to support the roof.[When a was in me Twenties - Forties...!] The Dr Pit was a "Naked Lamp Mine",under the M n Q Act 1954, so Willie Ward was ok using a Flashgun doon the pit,but wadn't hae been allowed doon any other "Flame Safety Regs " Pit.

-

2

2

-

-

Aye,James,the metal canister held 5 lbs of Explosive Cartridges,what we ,[the miners] referred to as "Sticks o' Pooda"..[Powder]. That was the Legal limit that a miner was allowed to carry,under the "Mines and Quarries Act 1954"..of course,like any other Industry,rules were made to be broken! Down the Three-Quarter seam,at Bates,in the early 1970's,I used to be hurrying inbye to fire the Solid Drivage Maingate or Tailgate,or Back Drift,[1-in-4 gradient!],carrying a 50 lb Box of Polar Ajax,[33% Nitro-Glycerine..],under one arm,another 50lb Box on the other shoulder,and TWO - 10LB Packs ,one each side inside of my Overalls!! So I was carrying 120 lbs of High Explosives,with my Glennie on my belt,my Self-rescuer,also on my belt,my Caplamp and Battery,which weighed 9lbs...Heh heh...I was only in my Thirties,and strong as an Ox!! Noo,aam nearly 77 yrs aad,and a canna lift me aan shadow! Four feet of lovely clean coal here,maybe 4' -6" ,and great dry conditions,gud hard laminated Sandy Post Stone..with a wee bit of Blue on top of the Seam. A great pic of times gone by! Thanks for posting it! Bill.

-

1

1

-

1

1

-

-

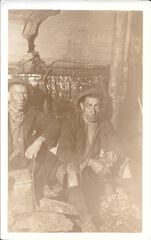

Hi Alan, thanks for sending this excellent, very rare, piece of historical Mining Memorabilia! I learned how to use the Vicious Sylvester from my first weeks down Seaton Burn Colliery, at the training gallery, underground, in 1959.It was designated specifically, as a pulling device, and lifting anthing with it was strictly forbidden.. well!.. theoretically! Although it was against the law to use it for lifting machinery, etc, what else could you use, if there was nothing else but the Sylvester! So! It was used for lifting, and over the years many lads lost fingers and thumbs at the very least, and at worst, some were knocked unconcious, and suffered fractured Skulls and Jaws, due to the "Butterfly" catch slipping and either taking fingers into the Sword, or the handle being viciously lashed forward by the weight of whatever was being lifted, usually a Coal cutter Stator, or a Conveyor belt Drive Head.. One lad at Bates, called Peter Brock, was using it correctly, pulling a conveyor belt return boxend, to tighten up the belt, to get it to run. Somehow, bizzarely, the Butterfly catch slipped, as it often did, and took Peter's thumb clean off. The Deputy dressed his hand, which was bleeding through the dressings, and as the Deputy went to phone the surface control centre, to organise an Ambulance, Peter said, seriously, to the Deputy, Eddie, aal just gaan and pull the boxend back, and get the belt gaanin.... The Deputy said a knaa wheor ye are gaaning, and its THIS way.. (pointing in the outbye direction!). Peter was back at work within a few weeks! If you ever saw a flicknife blade fly out, well, the Sylvester handle flew faster than that, it really was a vicious device, and by the later years, they were banned from use altogether.. but we still them had till the pits closed!

-

1

1

-

-

Number 6 isn't Jack Earl..nowt like him! He is my Wife's Brother..another photo in this gallery shows Jack correctly..there is no comparison!

-

Alan!..a thowt aa was gaan senile for a minute or three..needs re-title-ing methinks!

A left school in 1959,and aal these lads were me Brother's friends in class,most were me neighbours..aal three years aulder than me!!..they were mostly aal pitmen in 1959!!

Nitpicking,cos mind,aav nivvor seen any of these lads for donkey's' yeors!!

Great pics!

-

Heh heh!..so I was sort of right, in my supposition that it was a possibility that these steam haulers could be used underground. I have since learned by reading an article on "Disaster Glasses"..i.e.[Commemorative Glasses and other "Disaster Memorabilia.."], that these WERE the first haulage engines to be used underground,and did,in fact,have dedicated boilers,fired by coal,to generate the steam to operate them.

On the website article,regarding glass tumblers,which were engraved and sold in villages where disasters happened,it goes into lengthy detail on several Colliery Disasters,including all the local Collieries, and on one incident,a boiler had blown up,and the fatalities ,and injuries,to men and ponies,was horrendous.

It is an article worthy of reading,to those who are really interested in our Mining Heritage,and was entitled.."Disaster Glasses".

-

Aa was 15 years aad when aa started the pits straight from me school desk..in 1959...and aa was a little lad back then,aboot the height of the lads at the left hand side...and looking back noo,it was child labour even in more modern times compared to this era!

-

Those were the days when miners had to carry on working as long as they were able to..till health reasons made them retire!

Love the improvisation for a presentation table...two barstools and a well-worn coal-hoose door!

This looks like the 1950's to me,going off their suits,..oh!,and the old type cast-iron based Microphone stand in the background![I would notice that wouldn't I...being a musician..!]

Salt of the Earth,these guys,utmost respect to all of them...I followed in their footsteps,in 1971,for three weeks ,as part of my Deputy's course training,I was along with Dougie Moore,and Norman Smeaton,[Deputies in charge of me],and Bob Cowell was the Safety Officer..aal canny fellas,but mind a didn't care for the Undermanager at the time...Peter L....he treated me as if a was a five year aad kid!

Nivvor mind,Matty Smith was the Deputy's Union official,[Secretary or Chairman..canna mind which,but a smashing natured fella!]

Bob,if ye ivvor see these pics,a kept me word in your office..never forgot to this day how you helped me!

Thanks to Bob,and also to Carole for posting these great pics.!

-

...When Community spirit ruled!!

Great set of pics Carole!

-

Just a queer thought!,has anybody ever wondered why all the Winderhouses at the pits,had Church-like windows..["Cathedral-arches"]...?

Was it because it was sacrosanct that no-one was allowed in the Brakehouse,except the Brakesman,and other Authorised personell.

These window frames would have been a lot more costly to produce and maintain,than normal oblong ones!

-

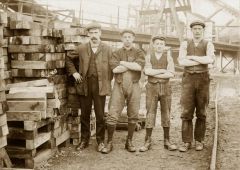

Great old pic!..notice the guy on the left,he would be the "Keeker",or man in charge of all surface operations,Dressed appropriately,shiny shoes,waistcoat,jacket,scarf!...could still have been a timberyard man,or worked on the screens,but not dressed like that,so yes,a chargehand.

I used to work with old fella's with one arm,or one leg,on the screens at Choppington High Pit,in 1959,the one-legged fella was a lovely gentle bloke,who had his leg blown off at the knee joint,by a bullet from his comrade's .303 rifle ,during the war,which happened because the rifle was loaded ,and dropped accidentally.

The viscious coal-cutter machine was also responsible for a lot of amputees,who ended up on "Light" work...sometimes working harder than they did underground!..ironically..

-

Just as a matter of further interest,the original post quotes the company as saying they make "Continuous rope haulage systems"...I would like to clarify the difference between a "Main and Tail " hauler,like this shown ,which had a "Main" rope,and a "Tail" rope...and a "Continuous" rope haulage system.

The two ropes swapped titles when the hauler was in a reverse mode..such that,when pulling a set of tubs inbye,the MAIN rope would be attached to the front of the set,and the TAIL rope would be attached to the rear of the set,usually with a "D"-shaped shackle,[we called them "Sheckles"],and a Sheckle pin to secure the rope within the sheckle and fastened to the middle "Cock-hole" of the tub.[ not obscene...the proper pit terminology for the holes in the tub at each end which is forged into the banding around the tub!]

The hauler driver would keep gentle braking pressure on the tail rope to keep it as taught as possible without overloading the hauler motor...and also to prevent the set from going "Amain"..[running out of control],down any anticlines..["Swalleys"].

When the empty set was ready to haul back outbye,the "Tail" rope would now be the "MAIN" rope,and vice versa.

Now on a continuous hauler,it was as the name suggests, a continuous loop of rope,which ran the full length of the rolleyway,[roadway],driven by a single-drum hauler,where the drum was only about a foot wide,and which had three coils of rope wrapped around the drum.

From the hauler drum,the rope was laid between the rails,and ran over floor mounted rollers placed about thirty yards apart,to help prevent the rope from sawing through the sleepers,which it did any way!..and also to reduce frictional drag on the hauler.

At the inbye end of the roadway,the rope went around a "Sheave",usually,but not always,mounted up on the girders in the roadway...sometimes the return Sheave was laid beneath the rolleyway..it depended which method of clipping the sets to the rope,was being employed...then the rope returned to the hauler slung up high in the roadway,and which ran over idler pulleys all the way back outbye,and being fed back into the hauler drum.[this was called the "Dead" rope. This system depended absoloutely on the correct tension of the rope between the hauler,and the return wheel..[the Sheave],to keep the three coils taut on the drum..in order for the hauler to drive the rope..without slipping on the drum.

Now I have given the scenario of a single -roadway system,where the driver had to switch over the hauler motor to reverse the rope direction,to bring sets outbye.

On shaft-bottom rolleyways,there were two rolleyways,a "Full " side,and a "Chum"..[short for Chumming..or empty ]..side.

The "DishLad",hung the sets onto the rope,from where the Chummings collected ,in a "Dish" [Swalley]...at the shaft-bottom area.

The Loader-end lad hung the full sets of coal tubs,onto the rope inbye,in order for the sets to be transported out to the shaft-bottom area. So in this case,there were two sheaves inbye,spaced so as to take the incoming rope from outbye,feed it across the roadway,and down onto the rolleyway leading the sets outbye.The rope usually ran continuously all shift,unless a fault occurred.

There was "Top-rope"haulage,and "Bottom-rope " haulage,whereby in the former system,the rope went over the tops of all the tubs in a set,using clips called either "Jockies" ,or "Hambones".[there was another stupid system using clips called "Pigtails"..which were highly dangerous in inexperienced hands...!]

Bottom rope haulage used equally dangerous systems ,such as the "Victor Dog Grip",Lashing chains,which were the ultimate deadly method of attaching a set to a moving haulage rope!,and in some cases Hambones again.

All of these systems involved the person,[usually young trainees for their first underground job],standing in front of a set of tubs or trams...whatever,and clipping whatever type of clip,or lashing chain,to a moving steel wire rope,which instantly jerked the set away from standstill,with very little,if any at all,time to jump back out of the way.

There were some nasty accidents,with serious injuries sustained,using these systems in the old days ....OLD days!!!...we were still using these clips and chains up until the day that thatcher-the-hatcheter gave the word to "SWITCH OFF AND PULL OUT EVERYONE"

The other deadly thing about haulage ropes were,they used to wear in places,and single steel wires,from their construction,would stick out,only an inch sometimes,what we called "Strands",and they used to catch hold of your boots,clothes,or your bare skin,with no mercy whatsoever.

Many a time I have been ripped by a strand,or pulled off my feet by a strand catching hold of my boot..there was no stopping these haulers,they used to rip out the supporting arched girders ,if a set got off the way[derailed],and the front tub went into the girders.

So back to the endless hauler system,at the inbye end,someone had to unclip the sets,still with the rope moving,unless Jockey's were in use,these unclipped themselves.

Google search for "PIT TUB HAMBONES,OR JOCKIES,OR PIGTAILS,OR VICTOR DOG GRIPS/CLIPS,OR LASHING CHAINS"

I canna think of any other method of clips used in my time,I would be interested to hear of any others used at other pits.

In the old days,1950's-on,for me,haulage ropes ran at four miles an hour,and the big shaft main and tail at Choppington,used to run at about eight miles an hour at full speed...now that's fast...underground!! where you have nowhere to to go except refuge manholes set into the road side every twenty yards apart....if you were in between those manholes,and a set was coming toward you!

In latter years haulage speeds were regulated to two miles an hour,which was still fast if you were following the set,in charge of it,and you tripped on a loose sleeper...it was away from you in seconds!

Hope I have explained clearly so the uninitiated can understand at least a wee bit better than before!

-

I just thought on,after I switched off last night,a while ago I watched a short film on U-Tube,which was a visit underground at Kellingly Colliery,[I think],and in one short clip,in the middle of the film,the Manager and his visitors went to jump onto a manriding conveyor belt,which would transport them away inbye.It was at a transfer point,where one conveyor belt loads onto another one,and high above the conveyor belt,hung from the roof,was a full-size mock-up of a horse hanging from the chains holding it,with a proper leather body harness, holding him in a comfortable position,simulating being slung from the cage,and being transported down the shaft,[or up the shaft,as the case may be.

The thing what struck me was...not one person glanced up to see it,they all had eyes down,and followed the Manager..Pidgeon fashion,onto the conveyor belt.

How nobody saw a full-size model horse hanging there...beats me,and I also thought that I wouldn't have wanted any of that lot as Marras working down there with me!!....you needed a hundred pairs of eyes,and instinctively learned to be aware of all your surroundings at all times...your life depended upon your vigilance,and common-sense! If I can find the film link,I will try and post it for your information.

Cheers !

HPW.

-

I hope I was clear enough to help you understand about these haulers,cos upon me re-reading again,I was thinking that you might have thought that this particular engine would have been used underground,which is not entirely impossible,but highly improbable!

It would have involved having a steam boiler within a short distance away,but seeing as the earliest pits depended upon a huge fireplace at the bottom of the upcast shaft,which heated the air,causing an updraught,which in turn,caused fresh air to be drawn down the "Downcast" shaft, which travelled all around the roadways of the pit,then I don't see why a boiler couldn't be installed into the fireplace..like a larger version of a domestic back-boiler,to provide the steam pressure necessary to drive this engine.

Ashington colliery,in Northumberland UK,still had the fireplace,along with all the fireman's rakes,and other tools which hung up on a large rack,on the side of the shaft walled area...it wasn't in use,naturally,after Electricity was installed at the mine,but it was a museum piece frozen in time!!..I think it all went to a Museum..not sure.

So my main point was that it was electric hauling engines that were used underground.

-

Laddies aboot 13 or 14 years old,and older ones....and we criticised other countries for using child labour!!

-

Netherton pit was relativeley dry,as was Bedlington A pit,and Ashington,as well as other pits I worked at,so looking at the scale of this engine,I am nearly 100 per cent certain that it would have driven the Colliery 's Ventilation Fan,which had a massive task to do!

-

Great pic!..completely different to the 100 years old steam winder at the High Pit!..mind,theres something about steam engines....Raw direct power,from massive twin cylinders,all the copper and brass pipework and valves polished like mirrors,and you just lay one finger on a pipe,as I did aged 15 years,and you got a steel pipewrench rapped over your fingers..as I had,from the Brakesman! they were very proud of their engines in those days...and that is fact!

-

A very good friend of mine lives in the Cottages opposite!

-

Netherton pit was unique then!At all pits,the ponies were stabled,fed,groomed,shoe'ed,and bedded down in the underground stables. Ponies were never put in a cage with a man!...they used to sling them in a proper body harness UNDERNEATH the cage,for the ponies own safety..he could kick and fling all he wanted..and wouldn't come to any harm.At Choppington High Pit,right up until it closed,in 1966,we had ponies sent down that weren't broken in at all.

We didn't have limbers [shafts] at all,until just before the pit closed,and that was only for one pony to supply the men driving a new drift.[scratching around for coal!].

We had what was called "Tracing Chains",which were two long chains,one each side,and attached to the pony's collar "Yem-sticks",and which had a hook at the end.

We used to trail all timber and steel materials across the bare rough ground..really hard labour for both the pony and his handler.[that was in all the Maingates.],and we had small trams with steel bars at the sides,upon which materials were loaded,and which were used in the Tailgates,with the pony's chains attached to each side of the tram...the roadways were too small too take pit tubs right up to the coalface,due to severe crush from the roof and sides.

We had to break the ponies in ourselves,by giving them twice as much of a load as we would normally,the pony would wildly try to escape the chains by straining and pulling constantly until he just tired himself out,and calmed down,then it was a case of a lot of love and attention,commands rewarded,as you would a dog or any other animal.

Once you bonded with your pony,and not a lot of miners did!!,he would do anything you asked him to do.

My gorgeous dapple grey Stallion,Charlie,had to be put to sleep after he suffered a serious injury underground,and I was in tears,and upset...in 1963,and even now,in 2019,aged 75 years,I still well up every time I see a rider passing on a Dapple-grey!

I watched the film.."Warhorse",just a few weeks ago,and I was breaking down watching the way the horses were treated,purely because of flashbacks to the conditions our ponies were subjected to..it was cruelty for man and horse at the High Pit...and the NCB and Government inspectors turned a blind eye to roadways so low that the ponies' backs and flanks were stripped to bare flesh bleeding,and having to be stabled for days,or weeks,untill they healed....sorry for ranting...wound up...thinking back...it wasn't like that at Netherton in 1971,I did a training course there for a few weeks,and saw how completeley different it was,and a lot easier on the pony's..better drier conditions made life a lot easier!

-

This is a main and tail hauler,[not a motor!..],used for hauling sets of pit tubs and trams, loaded with coal,and materials respectively.They were usually installed at the pit shaft bottom area,as the main means of transporting the total of the coal seam's requirements for a day.At the end of the roadway there would be "Return wheels",[or "Sheaves"],upon which the hauler ropes would be slung,and these wheels and blocks would either be slung up high in the roadway,or mounted beneath the rolleyway,at the end of the line.

Not nitpicking ,mind,only for correctness,but this not an electrically-driven hauler...it is a magnificent example of a twin cylinder steam - driven hauler.

In a very small,shallow mine,it could have been used to wind the pit cages in a not-so-deep mineshaft,it is a smaller version of the big winding engines...except these only had a single drum,with both ropes on the same drum.

Hope I have been of some help with this information.

Cheers

HPW.

-

...like a said earlier..not for the poor peasant coalminer,for the Officeworkers...Stone built frontage..a bit better class!

Luvly garden..and blinds at the windaes...!

-

Spotless clean street...nae litter in them days!

-

Brilliant set of pics throughout!

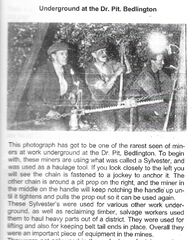

Putter Doctor Pit 1.jpg

in Historic Bedlington

4Posted

Andy is "Putting" or taking the tub outbye to a landing,where several full tubs would be coupled up,usually a set of six,where a "Driver" with a bigger horse would pull the set outbye from the landing to the shaft bottom,to be sent to Bank in the cages.Andy is going downhill when the pic was taken,as he has a wooden "Dreg" in the rear wheels to help slow the tub from over running the horse,even though the Limbers,["Limma's"] used to control the tub ,also the "Backstrap" on the Horse's Gears,around his rear end and fastened to his Bellyband...that pushed up against the Horse's rear flanks,and when he felt the pressure,he automatically pushed back against it and set his legs ..another great pic!